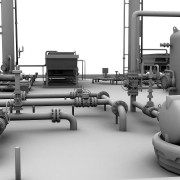

3 Reasons to Get 3D Models of Your Oil and Gas Facilities

In the oil and gas industry, there is no such thing as a perfect facility. As facilities age and the needs of your company change, you’ll always need to make changes and updates to make sure your facilities still meet those needs. The first step in any such oil and gas survey project should be to conduct 3D laser scanner surveying of the existing facility, which can then be used to create models. Having a 3D model of your current facility can provide you with a number of benefits that will help your update project run smoother.

The Three Main Benefits of 3D Models for Your Oil and Gas Survey

1. Greater accuracy

When planning an update to your existing oil and gas facility, it’s absolutely essential that you have a complete and accurate understanding of the facility as it currently exists. As you make decisions about what needs to be updated, you must be able to take exact measurements; just getting a basic idea of things won’t be good enough.

Having a 3D model of your facility supports this capability by providing an easy source of accurate information about the facility. These models are created using 3D laser scanning technology, which bounce thousands of laser points off the facility. As those laser points bounce back, the scanners will track the time it takes them to return and the flight path they follow. The scanners will then assemble a data cloud for all of those laser points, which is then used to support the creation of the 3D model.

Since your model will be based on the data taken from the laser scanners, you can feel completely confident that the data as accurate, and you won’t have to worry that you might be using inexact information gathered by hand.

2. Know about potential issues in advance

Anytime an unexpected issue comes up during the course of an oil and gas facility update, it can have serious complications for the project as a whole. The project team may find themselves having to completely scrap their original plan to account for the newfound issue, or at the very least delay the project while they try to work around it.

These delays and changes to the project plan can be extremely costly and time consuming, in addition to be a source of tremendous frustration for everyone involved. That’s why you’ll want to avoid running into such an issue if at all possible.

The whole reason these issues pop up when you’re not expecting them is because you lack a complete and accurate understanding of your facility. Having a 3D model gives you a simple and efficient method of looking for these issues. Once you’ve found them, having a model also makes it simple for you to come up with a plan that accounts for the issues, so that your project need not be interrupted as a result.

3. Spend less time on planning

Everyone knows that having a strong plan in place before you start on a project is an important part of ensuring the eventual success of that project. In spite of this, it’s still important that you be able to get through the planning phase as quickly as possible, so that you can get down to the actual business of making the update.

Using 3D laser scanning technology to generate accurate representations of a site can help you strike the proper balance between planning quickly and planning thoroughly. While these models are relative quick to create, they can still provide you with all the information you need to fuel a successful project.

To learn more about 3D laser scanner surveying as well as 3D models and how they can benefit your oil and gas project, contact Landpoint today.