4 Ways Pipeline Surveying Services Are Changing

As the oil and gas industry continues to evolve, pipeline surveying has become even more important. Pipeline surveying has to be completed both thoroughly and efficiently; an inaccurate survey can be environmentally dangerous and physically hazardous, while a lengthy survey can cost a business substantial amounts of money due to commercial commitments. New technologies have made it easier for pipeline companies to get the results that they need in a cost-effective way. Here are a few ways in which pipeline services are changing.

1. UAVs Are Becoming Commonplace

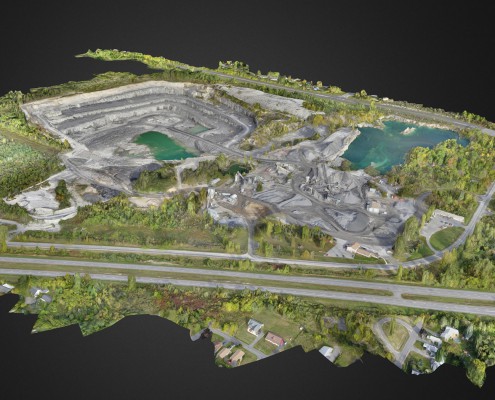

Drones, also known as UAVs (unmanned aerial vehicles), are steadily becoming more common throughout pipeline surveying. Traditional surveys were either done on foot or done by manned aerial vehicles. Neither of these were optimal solutions for many projects. On the ground, surveyors were often unable to get highly detailed information, needed to work slowly, and simply could not traverse some areas. In the air, manned vehicles were expensive and could not get high-resolution images of lower terrain. Both of these options were potentially risky to surveyors.

Comparatively, drones are great for pipeline surveying because they can cover large areas of the ground from a low vantage point, getting higher resolution images without any associated risk.

2. LiDAR is Being Used Interchangeably With Photogrammetry

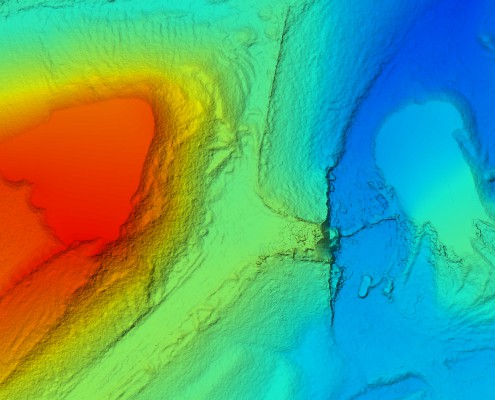

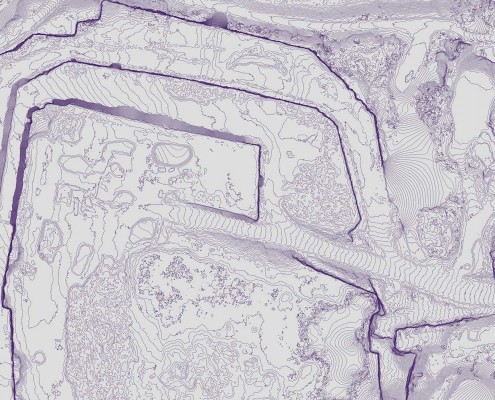

Another technology that surveyors are utilizing to deliver more accurate results is LiDAR and Photogrammetry. LiDAR is a method of surveying that uses lasers to map the ground below. This mapping can cut straight through underbrush, thereby producing more accurate pictures of the terrain. As 3D modeling and simulations become more important to the process of construction, LiDAR becomes the more popular type of surveying. In more open areas, photogrammetry is the method of choice for producing point cloud deliverables, which used photos and 3D representations of the land to create a model of the terrain.

Though LiDAR is better for some situations, it is also more expensive.

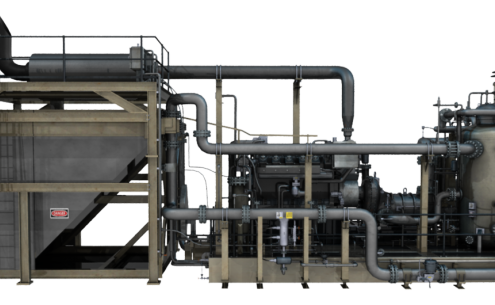

3. Working With End-to-End Providers

In the past, surveying companies may have worked with data analysis firms or may have outsourced much of their work to third-parties. Today, pipeline surveying is better done by companies that can provide end-to-end service, collecting their data and analyzing their own data to create better, more accurate, and more consistent results.

Advances in Software-as-a-Service technology and cloud-based data processing has made it possible for more surveying companies to handle their own data, reducing their reliance upon third-party processors. This reduces potential delays as well as improving the overall accuracy of the process, as data does not have to change hands.

4. Bringing Data to the (Hybrid) Cloud

It’s easy to see the influence of the cloud across all industries, and pipeline surveying is no exception. Through a hybrid cloud, organizations are now able to connect to their surveying data from anywhere, thereby making it easier for project managers, engineers, and construction teams to all work together. Cloud access can provide for more thorough reporting and analysis, and ensure that data is not lost. Data storage itself has become prohibitively expensive otherwise, as many organizations need to collect tremendously large volumes of data for their 3D models.

It’s easy to see how pipeline surveying may look in five or even ten years. Not only are UAVs going to be used more often, but the quality and accuracy of scans are likely to continue to improve. 3D modeling is going to become more important at the early stages of project development, and many construction companies may start using augmented reality and virtual reality during their pipeline surveying.

As of now, pipeline surveying has become a faster, easier, and more reliable process through the adoption of new data collection and analysis technologies. From the advantages of aerial drones to the data processing power of the cloud, pipeline surveys are now safer, more affordable, and more efficient.