How 3D Laser Scanning Services Cut Rework Costs

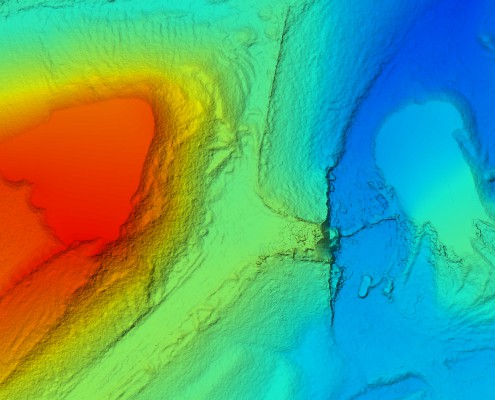

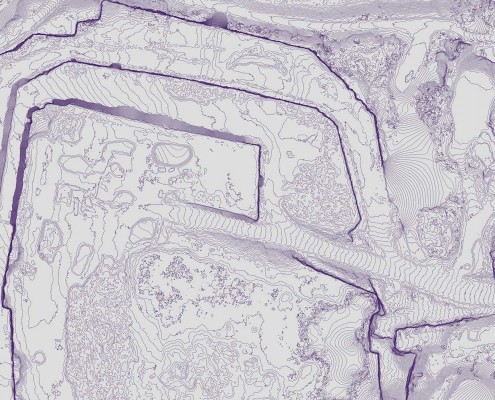

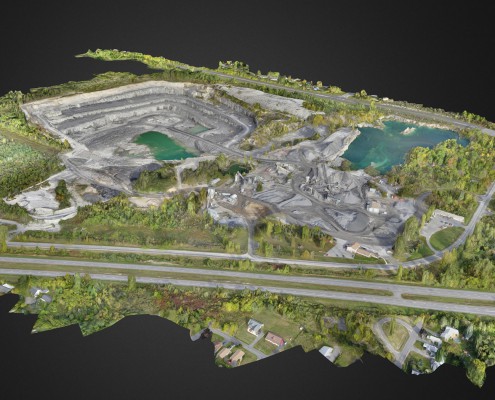

Reworks can account for up to 15 percent of the total cost of construction — but this cost can be alleviated through the use of 3D laser scanning services. 3D laser scanning, also known as high-definition surveying, is used to quickly scan, survey, and map large areas of land with complete accuracy. 3D laser scans can be ported into software solutions that are designed to simulate construction, thereby making it easier for companies to complete their projects with fewer mistakes and fewer reworks.

Lower Costs and Deliver On Time With 3D Laser Scanning

Laser scans can be used to produce more accurate plans from the start, thereby reducing the potential for reworks to as little as 1%. Through this increased accuracy, construction companies can greatly reduce their overhead and their bids, thereby making themselves both more profitable and more competitive within their field. Construction companies will experience fewer delays and will have more satisfied clientele, as projects will come in on time and on budget. Any investment in 3D laser scanning services can pay for itself through these reduced rework costs.

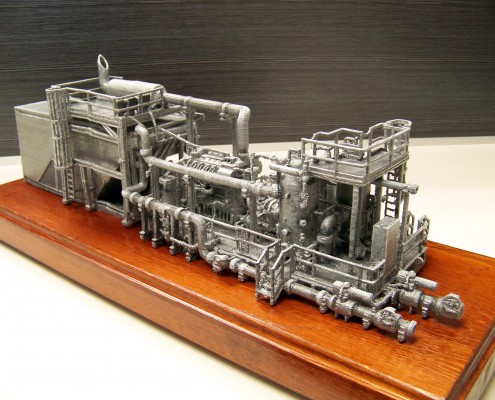

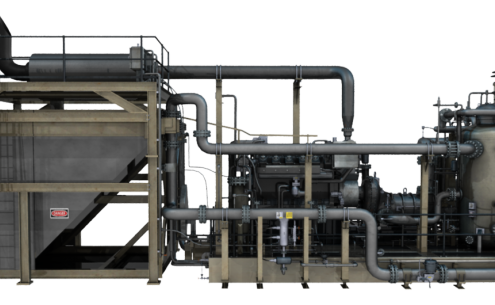

Laser scanning can be used at all levels of a new construction process. Not only can laser scanning be used for initial surveying, but it can also be used at intervals to assess structures. Laser scanning can be used to determine whether concrete floor slabs are flat enough, or whether the HVAC system, plumbing, and pipes are being installed correctly. Throughout the process of construction, 3D laser scanning provides a secondary check to ensure the accuracy and precision of the build. If anything goes wrong during construction, laser scanning can reveal the problems before they become monumental. In so doing, they give a construction company the opportunity to improve upon their project before problems arise.

Laser scanning can even be used throughout the process of renovation, to map the current structures and simulate and isolate potential changes. Through construction milestones, laser scanning provides for quality assurance, thereby making sure that the client gets the product delivered that they desired.

Ultimately, this doesn’t just lead to an on-time, on-budget project: it also leads to a better reputation and satisfied clientele. When fewer mistakes and reworks happen, it is also less likely that a mistake could make its way to a client, or potentially cause failure within the structure itself.

Reducing the Cost of Repairs, Maintenance, and Renovations

Laser scanning isn’t just useful during the initial project. Laser scanning creates a set of documentation, records, and 3D data that can be used throughout the rest of the project’s life. Repair work, maintenance, and renovations can all utilize this data, for more cost-effective solutions. This adds value to construction services and ultimately provides for happier clients long-term. Construction companies can provide continual support for their projects and sites through this data, as well as keeping the data for their archival records.

Laser scanning can be completed on multiple tiers of involvement and cost. Construction companies may want to do a single laser scan at the beginning of a project, to ensure that they aren’t missing anything about the lot, the environment, or a structure that is to be remodeled. Likewise, companies may find that they can improve their operations by completing laser scanning at intervals, inspecting the project as it grows and ensuring that the quality of the project is up to standards. More advanced laser scanning data can be used alongside sophisticated software packages, to simulate every aspect of a build. It’s all up to how much an organization can invest and how involved its project will be. For more information about how 3D laser scanning can improve the cost-effectiveness of your next solution, contact Landpoint.