Aerial Services

High-Precision Aerial Surveying

At Landpoint, we deliver comprehensive aerial data services powered by a team of certified UAS operators and geospatial experts. Our mission is to provide efficient, accurate, and data-driven solutions tailored to your project's unique needs.

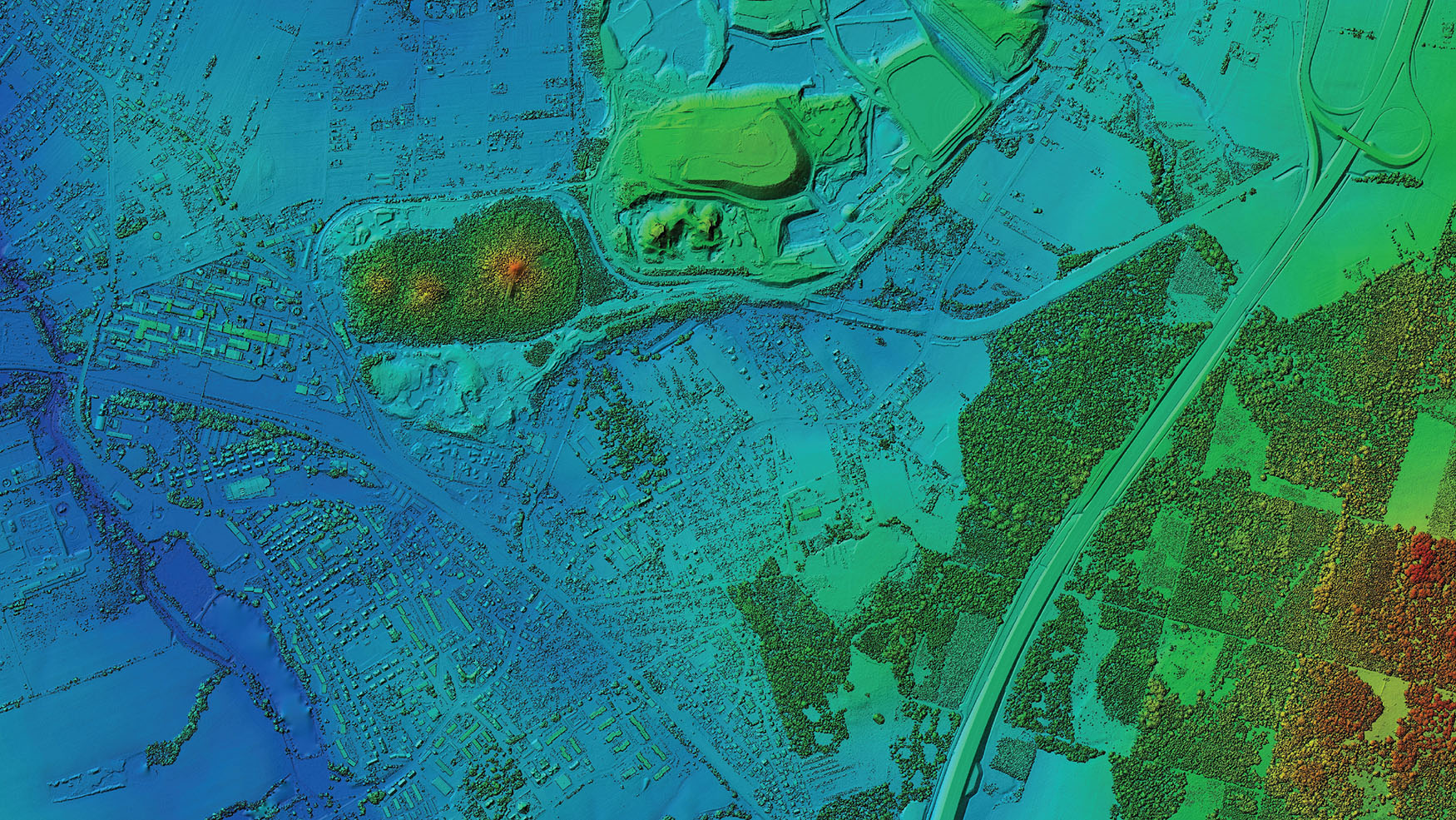

- Custom-Tailored Datasets: Leveraging industry-leading platforms and advanced sensors, we deliver precise datasets designed to meet your specific requirements.

- Survey-Grade Accuracy: Our data acquisition process, utilizing high-quality lidar and advanced imaging techniques, guarantees precise and dependable results.

- Actionable Insights: Empower your team to make informed, complex business and engineering decisions with confidence.

Discover how Landpoint’s advanced aerial solutions can transform your project from start to finish.

Services

The UAS Difference

Revolutionizing Data Capture with Cutting-Edge Aerial Solutions

At Landpoint, we leverage both manned and unmanned aircraft systems to deliver high-quality data for projects of any size. Our innovative approach ensures:

- Real-Time Insights: Collect data as frequently as needed to track ever-changing project conditions.

- Lightning-Fast Turnaround: Get the results you need, when you need them, without compromising quality.

- Survey-Grade Accuracy: Depend on pinpoint precision for every detail of your project.

- Advanced Technology: Harness the power of industry-leading lidar and imaging sensors.

Unlock the potential of your projects with the most reliable aerial data solutions available.

High-Precision Aerial Surveying

At Landpoint, we deliver comprehensive aerial data services powered by a team of certified UAS operators and geospatial experts. Our mission is to provide efficient, accurate, and data-driven solutions tailored to your project's unique needs.

Discover how Landpoint’s advanced aerial solutions can transform your project from start to finish.

Services

The UAS Difference

Revolutionizing Data Capture with Cutting-Edge Aerial Solutions

At Landpoint, we leverage both manned and unmanned aircraft systems to deliver high-quality data for projects of any size. Our innovative approach ensures:

Unlock the potential of your projects with the most reliable aerial data solutions available.

Safety Is Our Priority

Safety is paramount in land surveying due to the inherent risks associated with working in diverse and sometimes hazardous environments. Landpoint, LLC takes great pride in our company’s safety culture, reflected in our overall statistical successes. We firmly believe that all work can be completed with the highest safety and quality. Surveyors are trained to adhere to strict safety protocols and use personal protective equipment (PPE) to mitigate these risks. Implementing safety management systems, utilizing technology, and adhering to industry best practices all reduce risks and promote a safe working environment for land surveyors.